Fractal Fret Press v1.4

*March 2025 update: I am excited to announce the Fractal Fret Press is now exclusively available through www.StewMac.com!

https://www.stewmac.com/new/j-edwards-fractal-fret-press

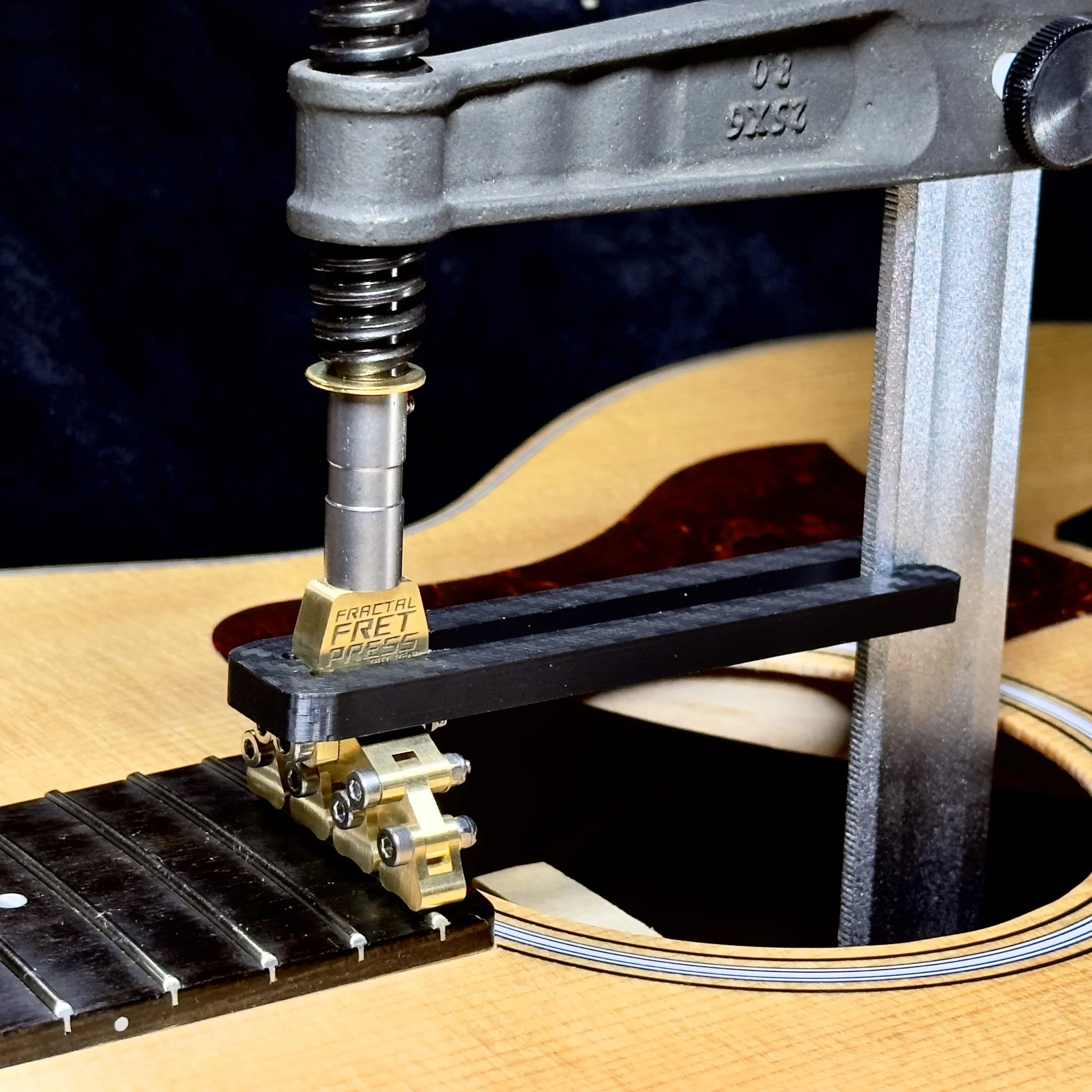

The Fractal Fret Press is a self-conforming radius caul designed to accurately install frets of any length on any radius without having to change or adjust anything on the tool. Quality of fret job is top priority of the Fractal Fret Press, but a happy by-product is time saved in the shop!

V1.4 Is compatible out of the box with the StewMac Jaws 2 fret press F-clamp system and reconfigurable for use with StewMac Jaws 1 fret press system locking pliers. Instructions for conversion of conversion here. Have an earlier version without the new Jaws 2 compatible stem? Reach out and I will send you one!

These tools are made by me in my shop with pride and love, deep in the heart of Texas!

See more details below

*March 2025 update: I am excited to announce the Fractal Fret Press is now exclusively available through www.StewMac.com!

https://www.stewmac.com/new/j-edwards-fractal-fret-press

The Fractal Fret Press is a self-conforming radius caul designed to accurately install frets of any length on any radius without having to change or adjust anything on the tool. Quality of fret job is top priority of the Fractal Fret Press, but a happy by-product is time saved in the shop!

V1.4 Is compatible out of the box with the StewMac Jaws 2 fret press F-clamp system and reconfigurable for use with StewMac Jaws 1 fret press system locking pliers. Instructions for conversion of conversion here. Have an earlier version without the new Jaws 2 compatible stem? Reach out and I will send you one!

These tools are made by me in my shop with pride and love, deep in the heart of Texas!

See more details below

*March 2025 update: I am excited to announce the Fractal Fret Press is now exclusively available through www.StewMac.com!

https://www.stewmac.com/new/j-edwards-fractal-fret-press

The Fractal Fret Press is a self-conforming radius caul designed to accurately install frets of any length on any radius without having to change or adjust anything on the tool. Quality of fret job is top priority of the Fractal Fret Press, but a happy by-product is time saved in the shop!

V1.4 Is compatible out of the box with the StewMac Jaws 2 fret press F-clamp system and reconfigurable for use with StewMac Jaws 1 fret press system locking pliers. Instructions for conversion of conversion here. Have an earlier version without the new Jaws 2 compatible stem? Reach out and I will send you one!

These tools are made by me in my shop with pride and love, deep in the heart of Texas!

See more details below

The Fractal Fret Press is not limited to compound radius fretboards! It can be used in traditional neck refrets or new builds, as well as experimental profiles and non-linear frets.

If you have found yourself refretting any number of guitars, you know the typical scenario all too well:

Grab a radius gage and inspect down the length of the board

Discover the radius is not exactly perfect or has extreme roll off on the edges

Settle on whatever radius is the closest and dig through the toolbox for the right caul insert then chase with the next step down just to make sure the fret ends actually get seated

Just for good measure, hit it again with the next insert a step up

That is three inserts used to ensure even contact across a fret for one standard fret job. Forget about compound radiuses; instead get out the hammer!

The need to dig through your toolbox and search for the closest radius insert is over. Go from a vintage guitar refret to your modern compound radius guitar build without the need to change or adjust anything! The self-conforming contact points equalize pressure when met with resistance of the fretboard and match its shape for a gapless fret install.

What about width?

An incredible amount of thought went into this tool. Its size is intentional to offer flexibility and consistency across any fret job while prioritizing quality of fretwork. The end to end contact points of the tool span 1.5 in. This is narrow enough to ensure the ability to seat the narrow first fret of a Jazz bass. The tools’ gentle and even pressure allows for use on any width of fret whether gradually pressing across the fret in steps or seating one half of a fret completely. The picture to the left features the torture test for this tool. It is a compound radius fret board featuring 35 frets with a width of 1.5 to 3 in. wide and a compound radius that ranges from 9.5 to 16 in. Even the widest 3 in. fret with 0.5 in. overhang was seated completely and evenly by using a segmented pressing technique. Check out the Testimonial Page to see what professional luthiers across the world are saying!

Bending fret overhang

There are many benefits of using this tool, some of which are not obvious. Traditionally, a hammer strike may eject a well seated fret when the overhang is struck. With the Fractal Fret Press, three feet can prevent the fret from unseating while the fourth foot applies pressure downward to achieve the over bend. This creates a perfectly seated fret, end to end.

Includes:

1 - Fractal Fret Press v1.4 with 3/8” stem compatible with StewMac Jaws 2 and arbor press

Jaws 2 hardware:

1 - 1/4” Brass bearing washer

1 - M3 thumb screw with nut (optional over preinstalled set screw on stem)

1 - “Torque Fork” 3D Printed clip for locking the Fractal Fret Press perpendicular to the Jaws 2 clamp. (.stl file is available to download here)

Jaws 1 reconfigure kit (requires modification. Instructions here)

1 - M3x14 mounting screw

1 - 4mm to 3mm brass reducer tube

2 - 4mm ID .5mm thick brass washers

The simplicity of the design makes it a straight forward and easy to use tool. However, please note that this is unlike anything before it and is a precision tool designed for use by a skill craftsperson. All fretwork demands properly sized and prepared fret slots. It is especially true of this tool. If excess pressure is required to overcome poorly slotted fret slots, damage to the fret crowns, fretboard and the tool may occur. The fret board must be perpendicular to the tool. Work hardening marks on the contact points of the tool are normal, and will not affect the performance of the tool. If you have any questions or need tips on use, please contact me.

Made by me in my shop with pride and love, deep in the heart of Texas.